Site Search

Search within product

第739号 2022 (R04) .04発行

Click here for PDF version

農業と科学 令和4年4月

本号の内容

§スマート農業連動土づくり・次世代型

基肥一発可変施肥体系による主食用米の多収技術

株式会社ファーム・フロンティア 取締役会長

Visiting Professor, Faculty of Agriculture, Yamagata University

藤井 弘志

§土のはなし−第10回よい土の条件のまとめ

−どんな土でも必ずよくなる−

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

Smart Agriculture Linked Soil Preparation, Next Generation

基肥一発可変施肥体系による主食用米の多収技術

株式会社ファーム・フロンティア 取締役会長

Visiting Professor, Faculty of Agriculture, Yamagata University

藤井 弘志

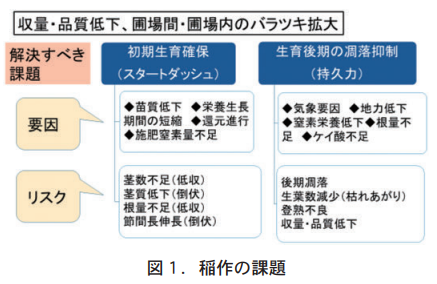

1. current rice crop productivity issues

Figure 1 summarizes the current issues in rice cultivation. Factors that lead to increased variation in growth and yield among and within fields, as well as lower yield and quality, include (1) suppression of early growth (dash start) and (2) wilting in the late growth stage (reduced endurance). Factors that suppress the dash start include low seedling quality, shortened vegetative growth period, progressive reduction, and reduced nitrogen fertilizer application, resulting in insufficient number of stems (low yield), low stem quality (collapse), insufficient root mass (low yield), and increased internode length (collapse).

Factors contributing to low endurance include weather factors (e.g., high temperatures), low soil fertility, low nitrogen nutrition, insufficient root mass, insufficient silicon, and water management, resulting in late-season wilting, reduced number of leaves (wilting), poor ripening, and lower yield and quality. To solve these problems, it is necessary to improve the dash to ensure early growth and the endurance to control wilting in the late vegetative stage.

Negative factors for endurance in terms of nitrogen nutrition in the leaf blade can be considered as follows. A decrease in nitrogen concentration in the lower leaves (increased senescence pressure in the leaf blade) will require nitrogen from the rice plant, in which case translocation from the lower leaves to the upper leaves will be enhanced. If the wilting of the lower leaves is caused by nitrogen translocation to the upper leaves due to nitrogen deficiency, late wilting occurs, resulting in lower yield and quality. This tendency is more pronounced in fields with low soil fertility and in high temperature years.

On the other hand, in rice paddies with high soil fertility, the nitrogen supply is derived from soil fertility, and the concern about a decrease in nitrogen concentration in the lower leaves is considered to be low (low senescence pressure). However, in rice paddies with poor early growth in recent years, it is assumed that a decrease in nitrogen concentration in the lower leaves occurs early after the ear setting stage due to insufficient root mass.

2. development of high-yielding staple rice technology based on smart agriculture-linked soil fertility and next-generation base fertilizer application system with one-shot variable fertilizer application

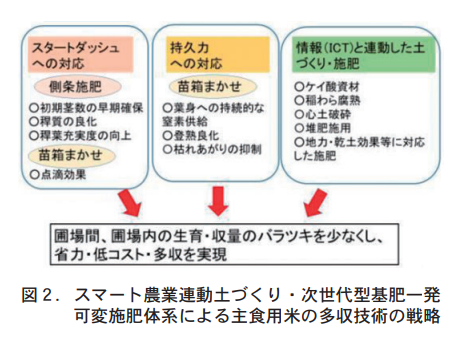

(1) Strategy for realization

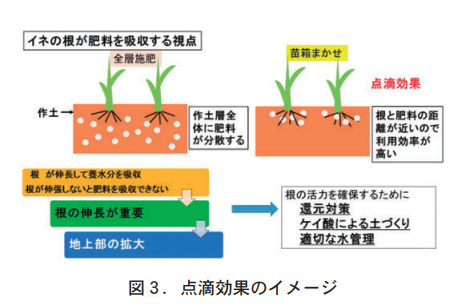

実現するための戦略は,図2に示すようにスタートダッシュへの対応として側条施肥(初期茎数の早期確保,稈質の良化,稈葉充実度の向上)と苗箱まかせによる「点滴効果(図3)」 ,持久力への対応として苗箱まかせ(葉身への持続的な窒素供給,登熟良化)と情報と連動した土づくり(ケイ酸質資材,稲わら腐熟)を併用することにより,圃場間,圃場内の生育・収量のバラツキを少なくし,省力・低コスト・多収を実現する技術を開発しました。

水稲の反応としては,側条施肥+苗箱まかせ(点滴効果)によるスタートダッシュで早期に必要とする茎数の確保(下位分げつ)がなされ,生育調節(深水,中干し)を十分に行うことが可能となりま(1茎乾物重の重い茎の確保) 。さらに,効率的な土づくり効果と苗箱まかせによる窒素供給による生育後期の持久力(後期凋落の抑制,窒素栄養の維持)を向上できる体制が確保されます。これらの技術開発によって,現状の稲作の反応である初期生育,根の伸長が不良で必要な茎数確保が遅れ,中干しなどの生育調節も適期対応が不十分になり,結果として根量が抑制され,生育後半の窒素供給不足も重なり,葉色低下や枯れあがりが発生し,気象災害(高温など)に脆弱な体制を変革することが可能となります。

(2) Strategies linked to smart agriculture (creating plots with less variation)

現在の圃場間,圃場内の生育・収量のバラツキを少なくするシステムは,ドローンセンシングで撮影した生育データに基づき可変施肥(無人ヘリによる追肥,次年度のGPS搭載ブロードキャスターによる基肥)による対応が行われています(圃場間・圃場内のバラツキがあることを前提にした対応)。しかし,この方式だと毎年,ドローンセンシングして可変施肥を行う必要があり,コストと時間がかかります。

Therefore, as a next-generation system to reduce variation in growth and yield between and within fields, we will develop a "less variation field" by combining (1) soil preparation (siliceous materials, rice straw rotting) linked with map information and sensing image information, and (2) fertilizer application system linked with map information (soil fertility, dry soil effect). The system is also used in conjunction with a fertilizer application system based on map information (soil fertility, dry soil effect).

0Information-linked soil preparation concept

Based on information from soil analysis and questionnaires (map information), we implement silicic acid materials and rice straw rotting systems for each field, select and concentrate soil preparation sites between and within fields based on sensing image data, and optimize the selection of silicic acid materials and spraying methods using an information system. We will reduce variation in soil fertility, reduce reduction of reduction, and promote early growth and suppress late wilting.

Concept of 0-information-linked fertilizer application

水稲が吸収する地力窒素の変動要因である圃場の地力評価(地域変動)と乾土効果評価(年次変動)を加味して,圃場毎の施肥窒素量を可変することにより,圃場毎の地力のバラツキを少なくすることが可能となります。具体的には圃場の地力(地域変動)と乾土効果(年次変動)等の情報(マップ情報)に基づいた側条施肥(速効性N:基肥相当)の窒素量の最適化により圃場毎に可変施肥を実施すること,地力・品種・収量目標・気象条件に基づいた苗箱まかせ(緩効性N:追肥相当)の窒素量の最適化により窒素量・肥料タイプを圃場毎に決定します。

Fertilizer "run-out" evaluation, inter-field and intra-field soil fertility evaluation by 0-sensing

Optimizing the use of additional nitrogen by constructing a system for determining fertilizer use based on information such as image diagnosis using drone sensing, growth speed after transplanting, and weather conditions (temperature and hours of sunlight); understanding the variation among and within fields; and responding to variable fertilizer application for soil preparation by understanding the reduction of We are also working to reduce variation among and within fields.

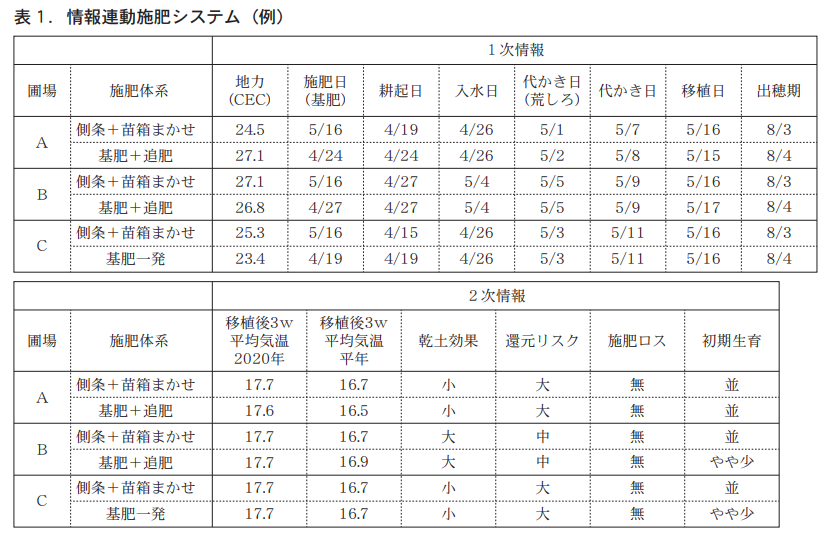

Table 1 shows the actual information processing using the information-linked fertilizer application system. (1) Secondary information is created from the primary information, (2) the nitrogen amount of side-row fertilizer (equivalent to base fertilizer) is determined from the primary information (soil fertility) and secondary information (dry soil effect), and (3) the amount of nitrogen applied to the seedling box (equivalent to additional fertilizer) is determined from the primary information (variety, soil fertility, weather, yield, etc.).

Demonstration and research on high-yield staple rice technology based on smart agriculture-linked soil fertility and next-generation base fertilizer application system with one-shot variable fertilizer application

(1) Testing method

We conducted a demonstration test in 2020 and 2021 using rice paddies with high soil fertility, setting up a control area with farmer's practice and a test area with side-row fertilization and seedling box-applying.

(1) Sample type: "Haenuki

(2) Test plots: Control and test plots were set up in 30a plots (two plots).

Composition of 0 test area

Control area (farmer's practice)

Field A (2020, 2021): total basal fertilizer ⇒ fast-acting

Nitrogen (55%): slow-release nitrogen (45%)

Plots B (2020) and C (2020, 2021): Base fertilizer nitrogen, fertilizer nitrogen ⇒ fast-acting nitrogen

Plots A and C (2021): Soil preparation (60 kg/10a of siliceous material (steel slag) applied)

Test area (side-row fertilizer application + seedling box)

Plots A, B, and C: Side-row fertilization ⇒ fast-acting nitrogen

Plot A: "Seedling box leave" 2020 ⇒ LPs100 (100 types), 2021 ⇒ LPs100s (80 types)

Plot B: "Seedling Box Leave" 2020 => LPs100s

Plot C: "Seedling Box Leave" 2020, 2021 ⇒ 100s of LPs

Plots A, B, and C: Soil preparation by information use (application of 60 kg/10a of siliceous material (steel slag))

(2) Weather conditions

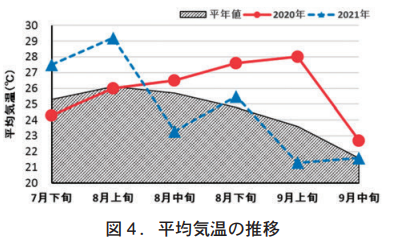

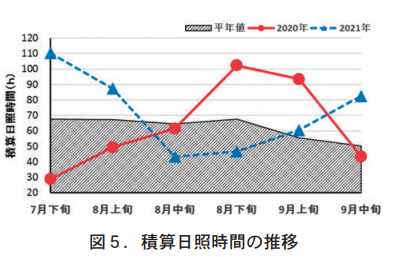

出穂期は,2020年が8月3〜4日,2021年が7月30〜31日でした。平均気温は,2020年が8月下旬から9月上旬に27℃の高温となり,2021年が7月下旬から8月上旬が27℃以上となり,特に8月上旬は29℃の異常高温で経過しました(図4)。

一方,日照時間は,2020年が7月下旬から8月中旬は平年値よりも少なく,8月下旬から9月上旬は多照で経過しました。2021年が7月下旬から8月上旬は平年よりも多く,8月中旬から8月下旬は平年よりも少照で経過しました(図5)。両年とも出穂後に高温で経過し,稲体の活力が消耗しやすい(夏負けしやすい)年次でした。

(3) Test results

(1) Evaluation of start-up

(1) Evaluation of initial growth

移植後27〜29日における初期生育(㎡茎数)および草丈×㎡茎数×葉色(≒窒素吸収量)は,対照区(農家慣行)に比べて,2020年・2021年とも試験区で優る傾向でした。早期に茎数を確保することは,第3〜6節の一次分げつ(強勢茎)を確保することになります。第3〜6節の一次分げつは,それ以外の分げつに比べて分げつの発生頻度が安定し,穂への有効化率が高く1穂精玄米重が重いことが指摘されています。早期に分げつを確保できることにより,生育調節(深水,中干し)を確実に行うことができ,弱勢茎の発生を抑制し早期に確保した強勢茎を太くし稈質の強化を図ることにつながります。

In recent years, there have been many cases of poor early growth and delayed growth adjustment (drying out), resulting in insufficient root mass due to inability to dry out the seedlings. To get a head start, it is an important strategy to secure strong stems at an early stage by applying side-row fertilizer and leaving the seedlings in the box (drip effect) to allow time for subsequent growth adjustment.

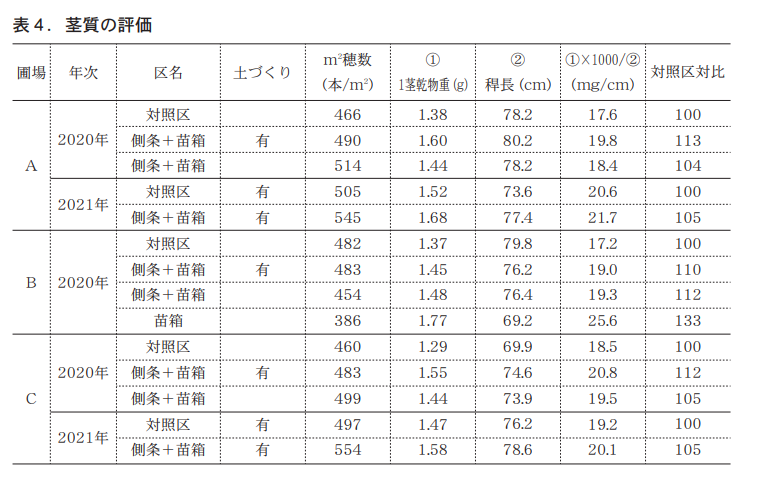

(2) Stem quality evaluation

対照区(農家慣行)に比べて側条+苗箱の試験区で,茎質(稈)の充実度(太さ)が高く,稈のバラツキが少ない傾向でした(表4)。稈充実度が高いことが,多収や気象変動に強いイネの創出につながります。2020年の結果から,1茎重は土づくりを実施した試験区で,土づくりを実施しない試験区よりも優る傾向で,ケイ酸資材の施用効果が認められました。2021年は,対照区もケイ酸資材施用を実施しているので1茎重は2020年よりも向上する傾向でしたが,試験区は対照区よりも優る傾向で,両年とも茎質向上に「側条施肥+苗箱まかせ」が有用であることが示されました。

(2) Endurance evaluation

(1) Evaluation of leaf color during the ripening stage

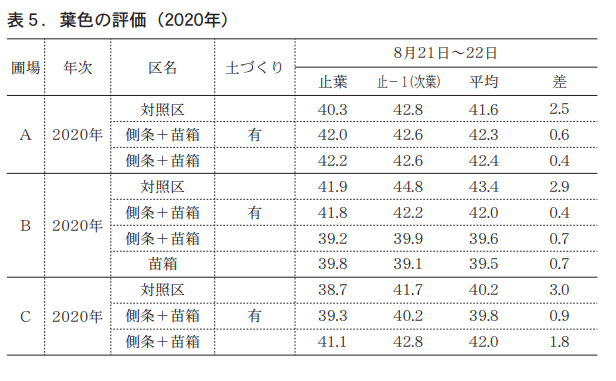

2020年の8月22日(出穂後18日)における試験区の葉色は,対照区と同等でした。止葉と止ー1(次葉)の葉色の差が,対照区に比べて試験区で小さい傾向でした(表5)。

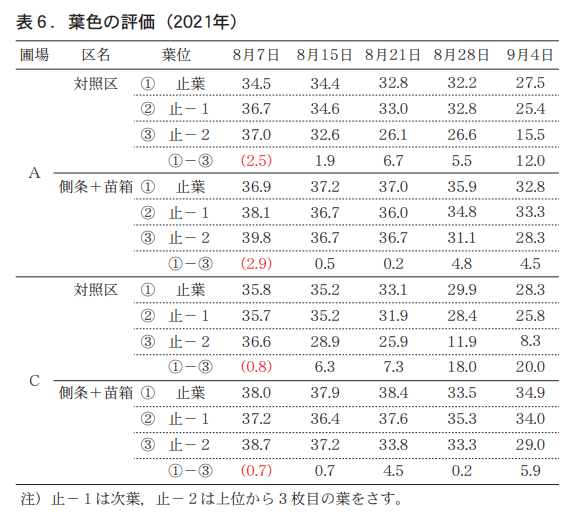

In 2021, the average temperature after ear emergence was higher than 29°C, so there is concern about wilting of nitrogen nutrition in the rice body.

れる年次でした。出穂期以降,約1週間ごとに上位から3枚の葉色の推移によれば(表6),対照区

In the case of the first two leaves, there is a large decrease in leaf color, especially in the third leaf from the top (the lower leaf), and withering occurs, and the later leaves are more susceptible to the disease.

The growth pattern is considered to be a wilted growth pattern, with high senescence pressure in the lower leaves and nitrogen translocation to the upper leaves, resulting in a wilted nitrogen nutrition of the entire rice plant body. On the other hand, the test area showed less decline in leaf color, and the lower leaves (the third leaf from the top) also maintained their color, resulting in less senescence pressure on the lower leaves and nitrogen nutrition of the entire rice body.

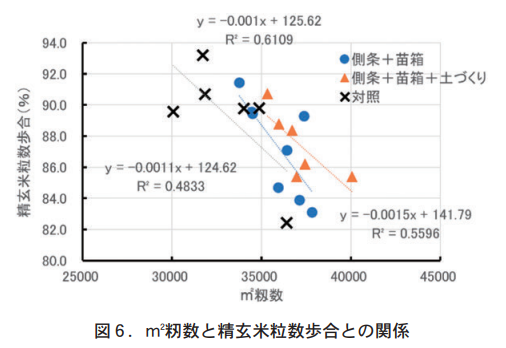

(2) Evaluation of climbing ability (Figure 6)

㎡籾数と精玄米粒数歩合の関係によれば,対照区に比べて試験区の方が,㎡当たり籾数に対する精玄米粒数歩合が向上する傾向でした。さらに,試験区にケイ酸資材施用区(製鋼スラグ)の方が,㎡当たり籾数に対する精玄米粒数歩合が高い傾向でした。

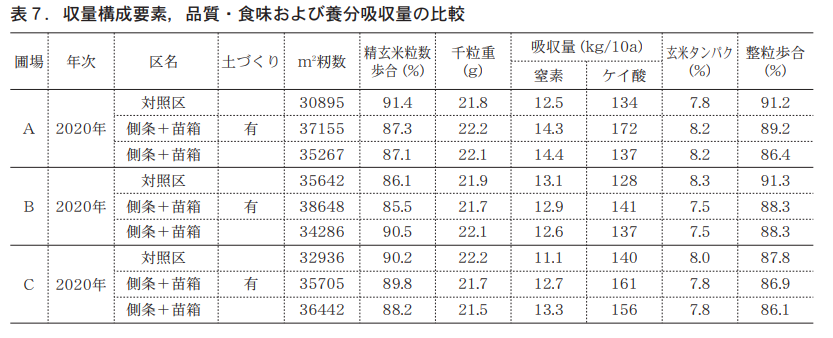

(3) Evaluation from yield components, quality/taste and nutrient absorption (Table 7)

収量構成要素からみると,㎡当たり籾数は試験区>対照区で,ケイ酸資材施用によっても増加する傾向でした。登熟の指標である精玄米粒数歩合(1.9mm以上玄米数)が試験区(側条+苗箱まかせ)で対照区よりも優る傾向でした。ケイ酸資材(製鋼スラグ)を併用した区では,登熟性や収量性がさらに優る傾向でした。

Yield was also higher in the test area than in the control area (farmer's practice). The combination of silica material (steel slag) tended to further improve the ripening and yielding performance.

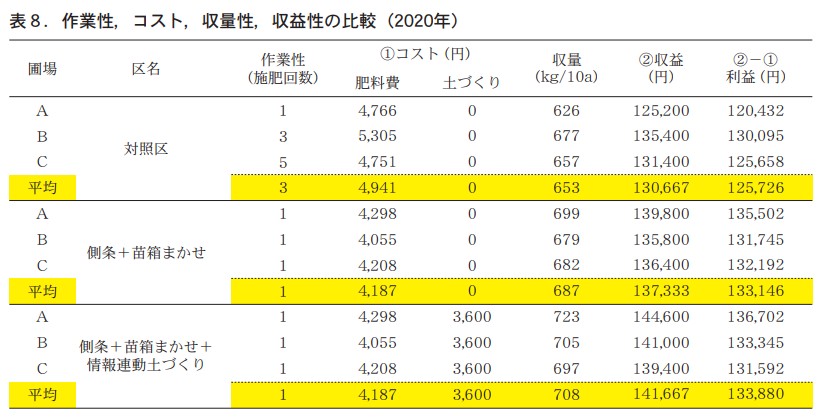

(4) Evaluation of labor savings, low cost, yield, and profitability

0 Workability evaluation(per 10a)

本田における施肥の回数は,対照区(農家慣行)では,A(全量基肥一発)で1回,B(基肥+追肥2回)で3回,C(基肥+追肥4回)で5回,平均3回でした。一方,試験区(側条施肥+苗箱まかせ)では各圃場とも1回で,対照区(農家慣行)よりも省力でした。

Evaluation of 0 cost

The cost of fertilizer application and soil preparation per 10 a was 4,766 yen, 5,305 yen, 4,751 yen, and 4,941 yen per 10 a in the control, B, and C, respectively, with an average of 4,941 yen. On the other hand, in the test area, the cost was 4,298 yen for A, 4,055 yen for B, 4,208 yen for C, and 4,187 yen on average, which were lower than those in the control area (farmer's practice). In the test plots where soil preparation was used in combination, each plot increased by 3,600 yen, with an average cost of 7,787 yen.

0Yieldability (10a yield)

In the control area (farmer's practice), yields were 626 kg, 677 kg, and 657 kg per 10 a, respectively, averaging 653 kg. On the other hand, in the test area, A699 kg, B679 kg, and C682 kg were produced, averaging 687 kg. The average weight of the test and silica material plots was 708 kg (A723 kg, B705 kg, and C697 kg). Compared to the control (farmer's practice), the test area yielded 34 kg more, and the area where the test area was combined with silicic acid material yielded 55 kg more.

0Evaluation of quality and taste (brown rice protein content)

Quality (grain yield) and brown rice protein content were almost the same in the control (farmer's practice), test, and test + soil cultivation areas.

0 Profitability evaluation

The average of the three fields was 125,726 yen in the control area (farmer's practice), which was 120,432 yen in A, 130,095 yen in B, and 125,658 yen in C. In the test area, the average of the three fields was 135,502 yen in A, 131,745 yen in B, and 133,192 yen in C. In the test area plus soil preparation, the average of the three fields was 133,146 yen in A, 136,702 yen in B, and 133,192 yen in C. In the control area, the average of the three fields was 133,146 yen in A, 133,146 yen in B, and 133,192 yen in C. In the test area and soil preparation area, A was 136,702 yen, B was 133,345 yen, and C was 131,592 yen, averaging 133,880 yen for the three plots. Compared to the control (farmer's practice), the test plot had an increase of 7,420 yen, and the plot where the test plot was combined with soil cultivation had an increase of 8,154 yen.

Therefore, the profit will increase by approximately 8,000 yen per 10a, 80,000 yen per 1 ha, 2.4 million yen per 30 ha, 8 million yen per 100 ha (large corporations), and 80 million yen per 1,000 ha (region) by "side strips + seedling boxes".

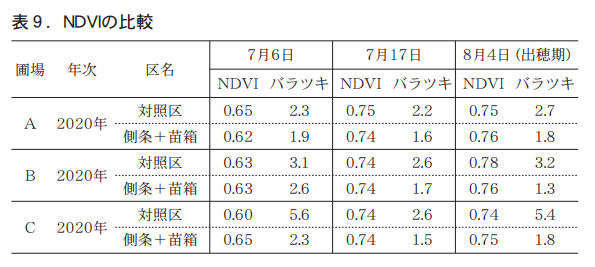

5) Variability evaluation of paddy rice growth (Table 9)

マルチカメラ搭載のドローンセンシングによる面的なNDVIの推移によれば(表9),A,B,C圃場とも撮影した出穂前29日,出穂前17日および出穂期の各時期ともNDVIのバラツキは,試験区で対照区に比べて低い傾向であり,面的な生育のバラツキが少ないことが示されました。

Summary

・スマート農業連動型として,マップ情報(土壌,作業,気象)とセンシング情報の利用により,圃場毎(圃場内の場所毎)の土づくり対応(ケイ酸資材,稲わら腐熟など)と圃場毎の地力・乾土効果情報(マップ情報)から側条施肥窒素量を設定するシステムを構築しました。

・次世代型の施肥体系として,「側条施肥(基肥相当)+苗箱まかせ(追肥相当)」の組み合わせで,水稲作の課題であるスタートダッシュ部分は側条施肥+苗箱まかせ(点滴効果)で,持久力部分は苗箱まかせで対応します。

・側条施肥により初期茎数の確保,早期に茎数の確保による1本当たりの乾物重の高い(太い)茎(稈質の良化,稈葉充実度が高い),稈長のバラツキの少ないことが確認されました。

・持久力についても登熟期間中の葉色の維持,止葉と次葉の葉色の差が小さいこと,「苗箱まかせ」から窒素が少しずつ供給され,イネが少しずつ吸収しているので老化圧力が低いことから下位葉の枯れあがりが少なく,最終的な登熟の指標である精玄米粒数歩合(1.9mm以上玄米数)が「側条+苗箱まかせ」区で対照区(農家慣行)よりも優る傾向でした。

・収量性も「側条+苗箱まかせ」区で対照区(農家慣行:基肥+追肥,基肥一発施肥)よりも優る傾向でした。ケイ酸資材(製鋼スラグ)を併用した区では,登熟性や収量性がさらに優る傾向でした。

・施肥回数の作業性,施肥代としてのコスト,収益性として収量(利益)の三点から評価すると,「側条+苗箱まかせ」の施肥体系は対照区(農家慣行:基肥+追肥,基肥一発施肥)に比べて省力・低コスト・多収の点で優ることが明らかになりました。

No Soil - 10th Summary of Good Soil Conditions

−どんな土でも必ずよくなる−

Jcam Agri Co.

北海道支店 技術顧問

松中 照夫

It has been a year since I began writing this series of articles in last May's issue. Over the past nine articles, we have discussed four conditions that must be met for soil to be good for crops. These four conditions and specific target values were described in the first article. From Part 2 to Part 9, each of these conditions and their target values were explained. This issue is a summary of these articles. I would like to review the relationship between the concept of good soil and soil cultivation.

1. what is soil preparation in the first place?

When farmers, as well as readers of this magazine, and others involved in agriculture discuss crop production and talk about soil, the word "soil preparation" always comes up. The final response is something like, "Soil preparation means the application of organic matter such as compost. The conclusion is that no matter what kind of soil or what kind of crops are grown, the first step in "soil preparation" is to apply compost, and if that "soil preparation" is carried out, it will lead unconditionally to good results.

I have an indescribable sense of discomfort with this fixed concept of "soil cultivation. If it were that simple, I would think that soil with poor crop production would soon disappear from the world. In short, it is only a matter of applying compost.

I consider "soil building" to be a practical activity to improve the soil of a target field to a soil that is good for crop production. In order to do so, it is necessary to clarify what factors in the soil of the field are inhibiting the growth of crops and to what extent. In other words, it is necessary to clarify which of the "four conditions for good soil" described in this series of articles is the greatest inhibitory factor to the growth of crops. Then, the practice of "soil cultivation" is the procedure of implementing measures to improve the conditions that have become the growth-inhibiting factors.

2. does good soil guarantee a high yield?

In reality, however, there is more at stake. Crop growth and yield are not determined solely by whether the soil on the farm is good for crop production.

Suppose there is a potato field with the best soil in Japan that satisfies all the "four conditions for good soil" through diligent improvement. However, no matter how good the soil is, if the temperature does not rise in summer, for example, the productivity (yield) of the potato field will be drastically reduced due to cold damage. Even if the weather is good, if the fertilizer is applied incorrectly, the potatoes will not produce well. Experienced farmers will be able to produce much higher yields than I, an amateur, can.

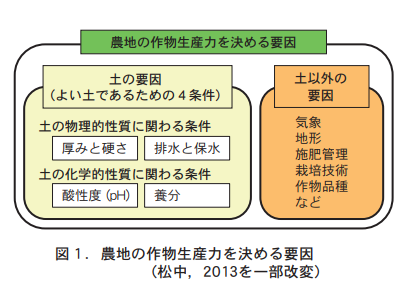

「土の作物生産力」と「農地の作物生産力」はちがう次元にある。土が作物栽培にとっていかによくても,農地としての作物生産力には,土以外の要因,たとえば気象や地形,立地環境,施肥や栽培の技術,さらに栽培する作物の種類や同じ作物でも品種のちがいなど多くの要因が関与しているからである(図1)。

3. soil is one of the factors that determine the crop productivity of farmland

In order for soil to have high crop productivity, it must satisfy all of the "four conditions for good soil," as described in this series of articles. However, it cannot be said that farmland with "good soil" that satisfies these four conditions will always produce a high crop yield. This is because "good soil" is only one of many factors that determine the productivity of farmland, as shown in Figure 1.

The more we value the soil, the more we feel that the soil always determines crop production. As a result, it is often said that "soil cultivation" is the most important factor in "improving crop productivity. Of course, there are many such cases. However, if we assume that soil is the only factor that determines crop production on farmland, we will lose sight of the real impediments to crop production. We must not forget that many factors are interrelated in determining the crop productivity of farmland.

The important thing is to be able to consider from a broad perspective what factors are responsible for the poor growth of crops grown on the farm. It would be a pity for the soil to blame the soil for all the causes of various phenomena, such as poor growth of crops. That is an overestimation of the soil. Before we assume that the soil is the cause, it is important to consider the factors that contribute to poor growth, and to accurately gather the factors that hinder growth.

4. the story of "the man who planted the tree" - any soil can always be made better.

I will never forget the words of my former teacher when I was a student: "Any soil can be made better. This is because I believe that even soil with many shortcomings will one day improve if we find out which of the "four conditions for good soil" are the factors that inhibit the growth of crops in that soil, and then do our best to improve those factors.

In particular, essential improvements in the physical properties of the soil cannot be achieved overnight by simply saying, "It will get better if you apply compost. It will probably not be possible unless the improvement measures are continued from generation to generation, from parents to children to grandchildren. The question is whether we will be able to sustain our efforts to improve the situation until then without giving up and without giving up tirelessly.

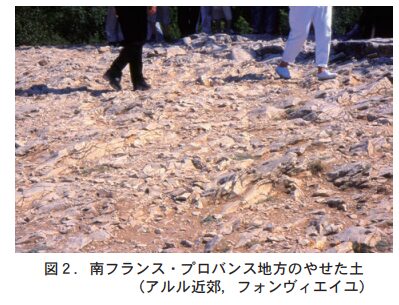

ジャン・ジオノというフランスの文学者がいる。彼が生まれた南フランス・プロバンス地方の土は,表層土の厚みが薄く大理石(石灰岩)がすぐに見えるようなやせた土が多い(図2)。しかし,彼は生涯生まれ故郷を離れることなく,その土地を愛し,その土地で文学作品を書いた。代表作がよくご存じの「木を植えた人」である。プロバンスのやせた土に木を植え続け,森や川を復活させ,人の心の潤いまで取りもどすために力をつくしたエルゼアール・ブフィエの物語である。

Selflessly and without asking for anything in return, day in and day out, he drilled holes in the barren, marble-covered soil and planted acorns in them. This act transformed the barren land into a land fit for people to lead healthy lives, both physically and mentally. I believe that with a sustained selfless practice like Bouffier's, any harsh, poor soil can be transformed into soil that can produce crops and in which people can live richly in mind and body.

What is necessary is to clarify what factors of the soil need to be improved and how, and then to continue with the improvement measures. We hope that you will utilize the "Four Conditions for Good Soil" to find these factors. To change bad soil into good soil for crops requires work like bouffier. Simply applying compost may miss the point.